How to Make a Blacksmith Hydraulic Press

time:2023-11-30 views:(点击 934 次)

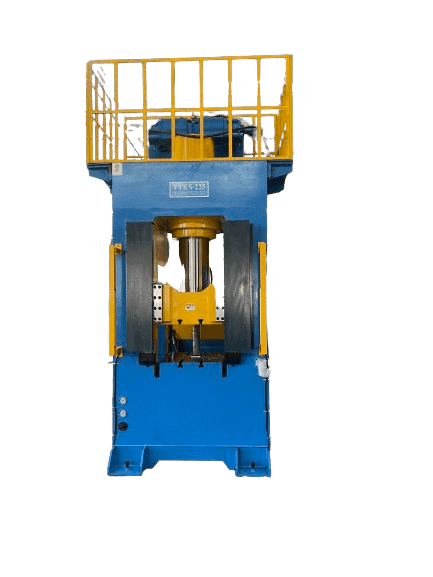

Blacksmith hydraulic presses can be essential tools for metalworkers. This apparatus enables blacksmiths to accomplish more with the material than could be achieved with just their hammers alone, giving them greater control.

Press forging creates a continuous grain structure, producing stronger and defect-free parts while increasing their elastic properties.

1. Decide What You Want to Make

First and foremost, you need to establish the purpose of your hydraulic press before making decisions and purchasing parts. For instance, if your goal is bending and forging, for example, you will require a double stage pump with low pressure (2-3 gpm) until it reaches 500 psi before switching over to high speed high pressure - this allows the ram to be quickly brought up to dies and forges while simultaneously keeping energy directed correctly towards preventing weld failure or misdirection of force.

Remember to shop around! Auctions, Craigslist, garage sales and flea markets can save you significant amounts of money.

3. Get the Tools You Need

Blacksmiths once used hammers and muscle power to shape hot metal for tools and farm equipment, but modern machinery such as forge presses now do this work more effectively. A forge press can be an essential tool across several industries; thus it is important that its applications, advantages, and maintenance requirements be understood well.

Forging is a metalworking process which aligns grain structures along its shape, producing stronger and more durable parts with less material waste. Furthermore, forge processes are more energy-efficient than other manufacturing processes and are widely utilized across several industries such as automotive manufacturing, construction and energy sectors - it is even capable of shaping different metals such as aluminum steel or brass!

Many blacksmiths rely on hydraulic forge presses as an indispensable part of their toolbox. This relatively small machine performs many of the same tasks as a power hammer but with greater control and precision, enabling them to take on more challenging jobs while expanding what can be made using hot metal.

As some smiths opt to build their own hydraulic forging presses, others prefer purchasing from trusted suppliers. No matter which approach you take, it's crucial that you select a quality machine that will last over time - shop around to find the best deals online and compare prices and reviews before making your decision.

An investment in training courses that will teach you to use the forge press is also recommended, providing essential skills and confidence needed to use it safely and efficiently. You will require various tools and equipment in addition to your forge press; such as heat source, cooling system and safety gear.

Press Master offers high-quality hydraulic forge presses that are simple to service and repair, as well as offering various models with customized options to meet your exact requirements. They even come equipped with their own service technicians! If you're in the market for an exceptional forge press, Press Master may have just what you're searching for! Their presses are made right here in North America so maintenance and repairs should not be an issue; plus there is plenty of variety when it comes to customization - find your ideal machine today.

4. Start Building

Presses can be invaluable tools in blacksmithing, but they won't solve every challenge that you will encounter along the way. At best, a press will speed up and simplify certain processes; but don't mistakenly believe that they're an all-in-one solution - they still require learning hammering techniques, Damascus pattern drawing techniques, forge welding processes and much more to succeed at blacksmithing!

Build your own hydraulic forging press for approximately $200! This project is ideal for home workshops or metal shops with limited power requirements; find parts at auctions, Craigslist and garage sales to complete it.

If you are building your own press, a double stage pump is highly recommended to ensure safety from potentially catastrophic failures that could kill. Industry uses board drop presses in closed die forging of thin materials like titanium and aluminum for this very reason.

Link to this article: https://www.ihydraulicpress.com/nsn/5536.html

Hot Articles

-

How to Make a Hydraulic Hash Press

Hydraulic hash presses are an efficient and simple way to produce high-grade rosin. Easy to operate, they can withstand considerable pressure with……

-

How Much Pressure Can a Hydraulic Press Apply?

Hydraulic presses use pressured liquid to force materials together, making them an incredibly flexible way of shaping metals or producing medicina……

-

How to Make Your Own Hydraulic Brake Press

Hydraulic press brakes rely on a complex hydraulic system to achieve up and down movements of their ram during bending processes, by pumping oil th……

-

How to Make a Hydraulic Press at Home

A hydraulic press employs fluid pressure generated by a motor to exert force upon a cylinder at a set force, using Pascal’s Law–where ……

-

How to Make a Hydraulic Press Machine at Home

Making your own hydraulic press at home is an affordable and useful way to add a powerful tool to your garage. A popular type is an H-frame press ……

-

Hydraulic Press Channel – How Much Money Does Hydraulic Press Channel Make?

Hydraulic Press Channel is a popular YouTube channel dedicated to crushing items with hydraulic presses. Established by Finnish factory owner Lauri ……

-

How to Make a Small Hydraulic Press

The hydraulic press is a machine that uses mechanical pressure to compress and shape materials such as metals, clay or wood. Additionally, this pres……

-

How Much Does Hydraulic Press Channel Make?

One can find it strangely captivating to watch objects get crushed with a hydraulic press, as witnessed on YouTube channel of Lauri Vuohensilta usin……

Latest News

-

Who Makes Black Widow Hydraulic Press?

Home mechanics or small repair shops will find this 20-ton air press indispensable, as it bends, shapes, and forms metal into various shapes or fo……

-

How to Make a 150 Ton Hydraulic Press

Hydraulic presses are machines that use pressure to force pistons into cylinders, often found in manufacturing, automotive repair or general shop ……

-

Hydraulic Press Channel – How Much Money Does Lauri Vuohensilta Make From Crushing Things With a Hydraulic Press?

Lauri Vuohensilta of Finland gained internet notoriety as the creator of Hydraulic Press Channel by crushing random objects with his hydraulic press……

-

How to Make a Small Hydraulic Hash Press

Hydraulic hash presses use a powerful jack to apply constant pressure to filter bags filled with bubble hash, forcing its trichome heads to rupture,……

-

How to Make a Hydraulic Press For Forging

Forging is a process in which slow pressure is used to deform materials into new shapes. It can be accomplished with either a mechanical press or hy……

-

How to Make a Homemade Hydraulic Press

Homemade hydraulic presses can be invaluable additions to the garage, helping users crush aluminum cans and other metallic objects with ease. Make……

-

How Much Money Does the Hydraulic Press Channel Make?

The Hydraulic Press Channel is a YouTube series dedicated to crushing objects with hydraulic presses. Started by Finnish workshop owner Lauri Vuoh……

-

How to Make a Hydraulic Press Brake

Press brakes are versatile metal fabrication equipment used for bending, folding and shaping sheet metal sheets with precise control by applying for……