hydraulic forging press

How to Purchase A Hydraulic Press In Yintong

-

1Online Consultation -

2Design a solution -

3Business negotiation -

4Assembly and production -

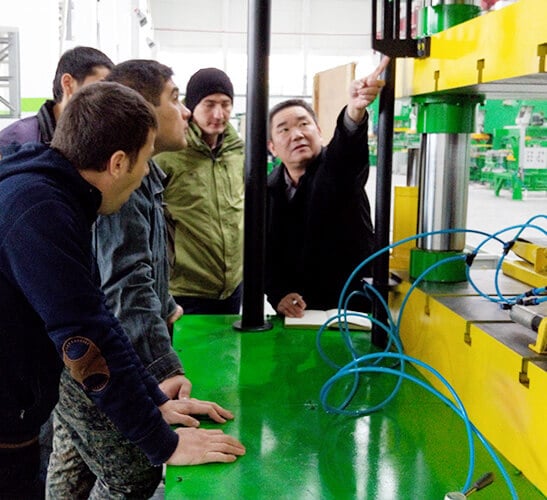

5Installation and testing -

6On-site installation

Why Yintong Hdraulic Press?

-

The world's top 500 cooperative suppliers

-

National-level high-tech enterprise

-

China Innovation Technology Fund Support

-

Recognized as high-tech products in china

-

2008 Quality Management System Certification

-

IQNET International Certification

Technical Parameter

Introduction:

The hydraulic forging press is a powerful and versatile machine designed for shaping and forming metal components in various industries. Over the years, hydraulic forging press manufacturers and hydraulic forging factories have continued to innovate and improve this essential tool, making it increasingly popular due to its numerous benefits, such as increased efficiency, precision, and reduced production times. In this article, we will provide an in-depth overview of the hydraulic forging press, its key features, its wide range of applications, and the advantages of working with reputable hydraulic forging press manufacturers and hydraulic forging factories.

Product Overview:

A hydraulic forging press utilizes the power of hydraulic fluid and pressure to generate the force required for forging operations. This innovative machine is capable of deforming and shaping metal materials into desired forms and sizes. The press's adaptability and flexibility make it ideal for various forging processes, including open-die forging, closed-die forging, and extrusion. Hydraulic forging press manufacturers and hydraulic forging factories have fine-tuned these machines to offer optimal performance and reliability.

Product Features:

- High Precision: Hydraulic forging press manufacturers have designed these presses to offer excellent control over the forging process, allowing for high-precision shaping and forming of metal components. This ensures a consistent and high-quality end product that meets stringent industry standards.

- Energy Efficiency: Hydraulic systems are known for their energy efficiency, as they can deliver a large amount of force with relatively low energy input. This translates to lower operating costs and a more environmentally-friendly production process. Hydraulic forging press manufacturers and hydraulic forging factories prioritize energy efficiency in their designs.

- Versatility: Hydraulic forging press manufacturers have made sure that these presses can be easily adapted to handle a wide range of materials and processes. Its versatility makes it suitable for various industries, including automotive, aerospace, and heavy machinery manufacturing.

- Enhanced Safety: With advanced safety features and built-in sensors, the hydraulic forging press ensures a safe working environment for operators, reducing the risk of accidents and injuries. Hydraulic forging press manufacturers and hydraulic forging factories have placed a strong emphasis on safety.

- Customizability: Many hydraulic forging press manufacturers and hydraulic forging factories offer custom-built solutions to meet the unique requirements of their clients. This means that presses can be designed and manufactured to accommodate specific production needs and material specifications.

Product Applications:

The hydraulic forging press has a broad range of applications across various industries. Some of the most common uses include:

- Automotive Industry: Hydraulic forging press manufacturers and hydraulic forging factories have contributed to the widespread use of these presses in the automotive industry for forging critical components such as gears, shafts, and engine parts.

- Aerospace Industry: High-strength and lightweight materials are essential for the aerospace industry, and the hydraulic forging press is perfectly suited to form these components with precision and efficiency.

- Heavy Machinery Manufacturing: Large and complex components for heavy machinery, such as construction equipment and mining machinery, can be efficiently forged using a hydraulic forging press, making them popular in this sector.

- Energy Sector: The hydraulic forging press is also used in the energy sector for manufacturing components used in power generation equipment and wind turbines, thanks to the advancements made by hydraulic forging press manufacturers and hydraulic forging factories.

- Marine and Shipbuilding: Hydraulic forging presses are used to produce high-quality components for the marine and shipbuilding industry, including propellers, shafts, and other critical parts.

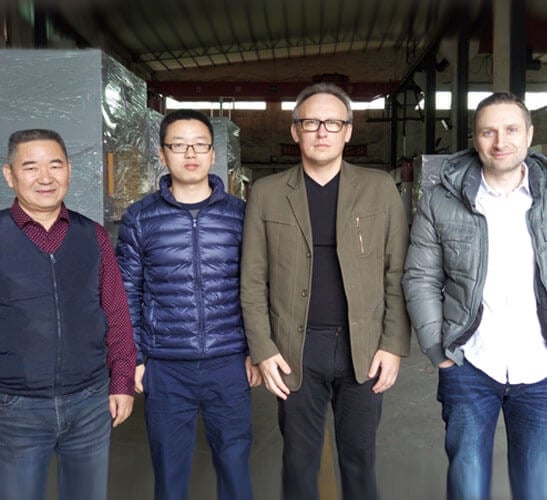

Production Cases

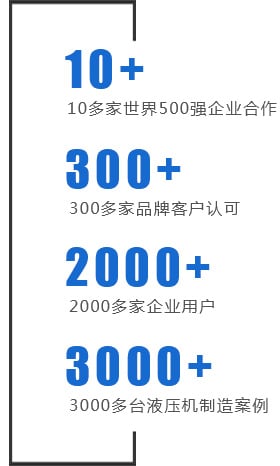

十二家世界500家企业的共同选择!

现有 5000多家客户

300多家品牌客户

世界500家企业长期的合作

-

ITALINA

-

雷士照明

-

索尼

-

三星

-

勤上

-

中国印钞

-

苏泊尔

-

華帝

-

格力

-

DFM

-

松下电器

-

正泰集团

-

LG

-

TCL

-

深圳职业技术学院

-

中国华录

-

比亚迪

-

美的

-

恒美

-

海尔

-

本科

-

万和

-

METALOR

-

ROBAM

-

中能

-

鸿特精

-

昆钢集团

-

JAGUAR

-

桂林航天工业学院

-

周六福珠宝

-

周大福

-

万新光学

-

海昌

-

坚朗

-

广福鑫

-

Schneider

-

日东集团

-

金六福

-

中国黄金

-

METALOR

-

华硕

-

CITIZEN

十三个国家和地区的客户共同见证!

Production Cases

-

hydraulic forging press

Introduction: The hydraulic forging press is a powerful and versatile machine designed for shaping and forming metal components in various industrie……

More> -

YT-RS Series 300 Ton Hot Press Molding Machine

Product application of 300 ton hot forging hydraulic press YTD series 300 ton servo hot press has six layers, including circulating water c……

More> -

-

产品咨询,索取报价

产品咨询,索取报价