YT-RS Series 300 Ton Hot Press Molding Machine

How to Purchase A Hydraulic Press In Yintong

-

1Online Consultation -

2Design a solution -

3Business negotiation -

4Assembly and production -

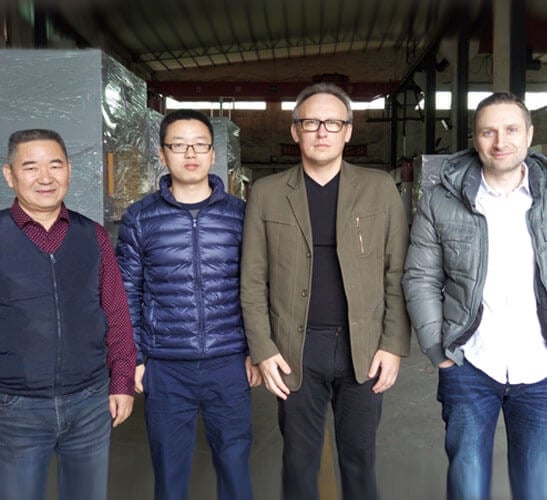

5Installation and testing -

6On-site installation

Why Yintong Hdraulic Press?

-

The world's top 500 cooperative suppliers

-

National-level high-tech enterprise

-

China Innovation Technology Fund Support

-

Recognized as high-tech products in china

-

2008 Quality Management System Certification

-

IQNET International Certification

Technical Parameter

Product application of 300 ton hot forging hydraulic press

YTD series 300 ton servo hot press has six layers, including circulating water cooling layer heat insulation layer and heating layer. The distribution is the same. Among them, the circulating water cooling layer is used to cool the machine to prevent the machine from being damaged or scalded. The middle part is the heat insulation layer. The material is polymer composite material, which has the function of high pressure resistance, no deformation and heat insulation. In order to prevent excessive heat loss, the heating layer is a heating mold.

| Model | YT-50RS | YT-100RS | YT-150RS |

| Nominal force output | 50 | 100 | 150 |

| Maximum hydraulic working pressure(MPA) | 21 | 22 | 24 |

| Back stroke force(Ton) | 5 | 10 | 15 |

| Height of table above floor(mm) | 780 | 780 | 820 |

| Biggest operational height(mm) | 400 | 400 | 550 |

| Maximun stroke of the ram | 300 | 300 | 400 |

| Dimensions of working table | Left-right(mm) | 1000 | 1200 | 1500 |

| Front-back(mm) | 600 | 700 | 800 |

| Speed of slide(mm/s) | Speed of down | 220 | 220 | 220 |

| Working speed | 20 | 20 | 20 | |

| Speed of returning | 190 | 190 | 190 | |

| Fever effective area | Left-right | 900 | 1170 | 1250 |

| Front-back(mm) | 550 | 650 | 750 | |

| Hair heat pipe | 460 | 560 | 750 | |

| Overal dimensions of the machine | 1300*1700*2480 | 1550*1900*2530 | 1850*2100*2850 | |

| Motor+fever=work rate(kw) | 3.7+10.5=14.2 | 3.7+13.5=17.2 | 4.5+17.5+22 | |

The Technical Features of 300 ton hot forging Hydraulic Press

- Using advanced hydraulic system, more steady, safer and more reliable.

- Pressure, stroke and pressure keeping can be adjusted according to processing requirement.

- Four columns are made of high-strength alloy steel with hard chrome plated surface and good abrasion resistance.

- The moving bolster and worktable are equipped with optional ejecting cylinder, which meets different ejecting requirements of

different products.

- Digital control is achieved with PLC programming circuit design and touch panel operating system

Production Cases

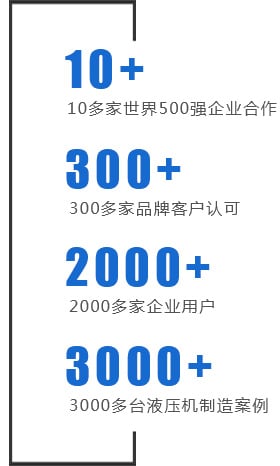

十二家世界500家企业的共同选择!

现有 5000多家客户

300多家品牌客户

世界500家企业长期的合作

-

ITALINA

-

雷士照明

-

索尼

-

三星

-

勤上

-

中国印钞

-

苏泊尔

-

華帝

-

格力

-

DFM

-

松下电器

-

正泰集团

-

LG

-

TCL

-

深圳职业技术学院

-

中国华录

-

比亚迪

-

美的

-

恒美

-

海尔

-

本科

-

万和

-

METALOR

-

ROBAM

-

中能

-

鸿特精

-

昆钢集团

-

JAGUAR

-

桂林航天工业学院

-

周六福珠宝

-

周大福

-

万新光学

-

海昌

-

坚朗

-

广福鑫

-

Schneider

-

日东集团

-

金六福

-

中国黄金

-

METALOR

-

华硕

-

CITIZEN

十三个国家和地区的客户共同见证!

Production Cases

-

hydraulic forging press

Introduction: The hydraulic forging press is a powerful and versatile machine designed for shaping and forming metal components in various industrie……

More> -

YT-RS Series 300 Ton Hot Press Molding Machine

Product application of 300 ton hot forging hydraulic press YTD series 300 ton servo hot press has six layers, including circulating water c……

More> -

-

产品咨询,索取报价

产品咨询,索取报价