YT-ZK Series 20 Ton hot vacuum press

How to Purchase A Hydraulic Press In Yintong

-

1Online Consultation -

2Design a solution -

3Business negotiation -

4Assembly and production -

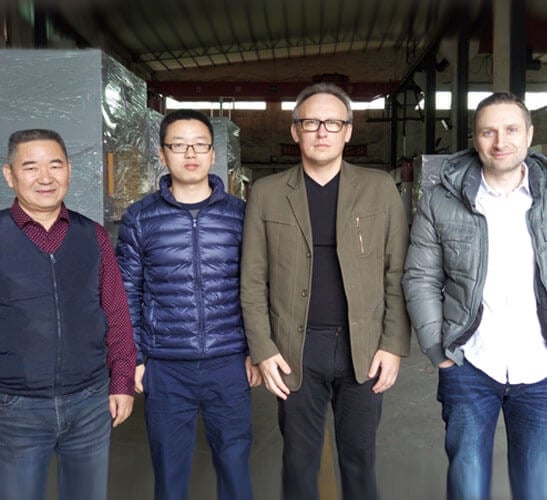

5Installation and testing -

6On-site installation

Why Yintong Hdraulic Press?

-

The world's top 500 cooperative suppliers

-

National-level high-tech enterprise

-

China Innovation Technology Fund Support

-

Recognized as high-tech products in china

-

2008 Quality Management System Certification

-

IQNET International Certification

Technical Parameter

Introduction of Hot Vacuum Press

The hot vacuum press is an innovative and versatile vacuum hot press designed for a variety of applications, including laminating, molding, and bonding materials in various industries. As leading hot vacuum press manufacturers and suppliers continue to refine and enhance this essential equipment, it has become increasingly popular due to its numerous benefits, such as improved efficiency, precision, and reduced production times. In this article, we will provide an in-depth overview of the hot vacuum press, its key features, its wide range of applications, and the advantages of working with reputable hot vacuum press manufacturers and suppliers.

Product Features of Yintong Brand Hot Vacuum Press

A Yintong brand hot vacuum press utilizes the combined power of heat and vacuum pressure to achieve various material processing tasks. This versatile machine can mold, laminate, and bond materials with high precision and uniformity, making it ideal for a range of applications in industries such as woodworking, plastics, and composites. Hot vacuum press manufacturers and suppliers have fine-tuned these machines to offer optimal performance and reliability.

- Rapid and Uniform Heating: Hot vacuum press manufacturers have engineered these machines with advanced heating elements that provide rapid and uniform heat distribution. This ensures even and thorough processing of materials, resulting in consistently high-quality products.

- Precise Vacuum Control: This kinds of hot press machine is equipped with accurate vacuum control systems that maintain consistent pressure throughout the process. This precise control allows for better material bonding, lamination, and molding, ultimately leading to superior end products.

- User-friendly Interface: Hot vacuum press manufacturers have designed these machines with easy-to-use interfaces, allowing operators to efficiently control temperature, pressure, and processing times. This user-friendly design ensures seamless operation and reduces the likelihood of errors during production.

- Low Maintenance and Durable Design:as this type of hot forging press is constructed with high-quality materials and components, making them robust and durable. This long-lasting design reduces maintenance requirements and overall downtime, contributing to increased productivity and cost savings.

- Compact Footprint: Hot vacuum press manufacturers have designed these machines with space-saving features, allowing them to fit easily into various production environments. The compact footprint of these presses enables businesses to maximize their available workspace without sacrificing production capabilities.

Product Applications of Yintong Hot Vacuum Press

The hot vacuum press has a broad range of applications across various industries. Some of the most common uses include:

-

- Woodworking Industry: The hot press machine manufacturers and suppliers have contributed to the widespread use of these presses in the woodworking industry for tasks such as veneering, laminating, and forming curved panels.

- Plastics Industry: High-precision and efficient molding of plastic components are essential for the plastics industry, and the hot vacuum press is perfectly suited for these tasks.

- Composite Manufacturing: The hot vacuum press is widely used in the production of composite materials, such as carbon fiber and fiberglass components, thanks to its precise temperature and pressure control.

- Furniture Industry: Hot vacuum presses are used to produce high-quality furniture components, including laminated panels and shaped elements, making them popular in this sector.

- Automotive and Aerospace: The hot vacuum press is also used in the automotive and aerospace industries for manufacturing lightweight and high-strength components, such as interior panels and structural parts.

Production Cases

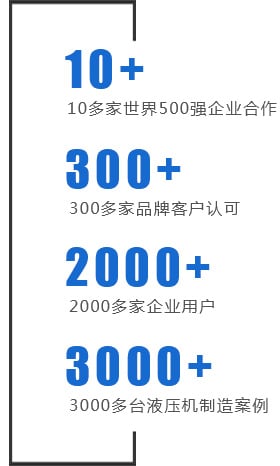

十二家世界500家企业的共同选择!

现有 5000多家客户

300多家品牌客户

世界500家企业长期的合作

-

ITALINA

-

雷士照明

-

索尼

-

三星

-

勤上

-

中国印钞

-

苏泊尔

-

華帝

-

格力

-

DFM

-

松下电器

-

正泰集团

-

LG

-

TCL

-

深圳职业技术学院

-

中国华录

-

比亚迪

-

美的

-

恒美

-

海尔

-

本科

-

万和

-

METALOR

-

ROBAM

-

中能

-

鸿特精

-

昆钢集团

-

JAGUAR

-

桂林航天工业学院

-

周六福珠宝

-

周大福

-

万新光学

-

海昌

-

坚朗

-

广福鑫

-

Schneider

-

日东集团

-

金六福

-

中国黄金

-

METALOR

-

华硕

-

CITIZEN

十三个国家和地区的客户共同见证!

Production Cases

-

-

YT-ZK Series 20 Ton hot vacuum press

Introduction of Hot Vacuum Press The hot vacuum press is an innovative and versatile vacuum hot press designed for a variety of applications, inclu……

More> -

YT-ZK Series 500 Ton Vacuum Hot Press

The Yintong YT-ZK series vacuum hot press is mainly suitable for pressing new materials by vacuum extraction.it is a kinds of hydraulic hot press ma……

More>

产品咨询,索取报价

产品咨询,索取报价